At Samson Metal in Lakeland, Florida, we are committed to delivering precision, efficiency, and quality in every project. As an AS9100D:2016-certified manufacturer serving industries such as aerospace, entertainment, and power generation, we leverage cutting-edge technology to meet the most rigorous standards. Central to our metrology capabilities is the Keyence WM-6225 Wide Area Coordinate Measuring Machine (CMM) Camera, a product from Keyence Corporation of America, which enhances our ability to produce high-quality components in our 53,000 sq. ft. facility. From our perspective, this advanced tool is a game-changer, and we’re excited to share its key advantages for our fabrication and manufacturing processes, as showcased on our website, www.samsonmetal.com.

1. Broad Measurement Range for Large-Scale Components

The Keyence WM-6225 offers an impressive measurement range of up to 25 meters (82 feet), enabling us to inspect the large components and assemblies common in our aerospace, power generation, and entertainment projects. Whether we’re verifying the dimensional accuracy of structural steel, pressure vessels, or amusement ride hardware, this system allows us to measure oversized parts without multiple setups or repositioning. For example, in aerospace, we use it to ensure the precision of welded assemblies, streamlining inspections and reducing handling time for heavy components. This capability reflects our ability to tackle projects of any scale with confidence.

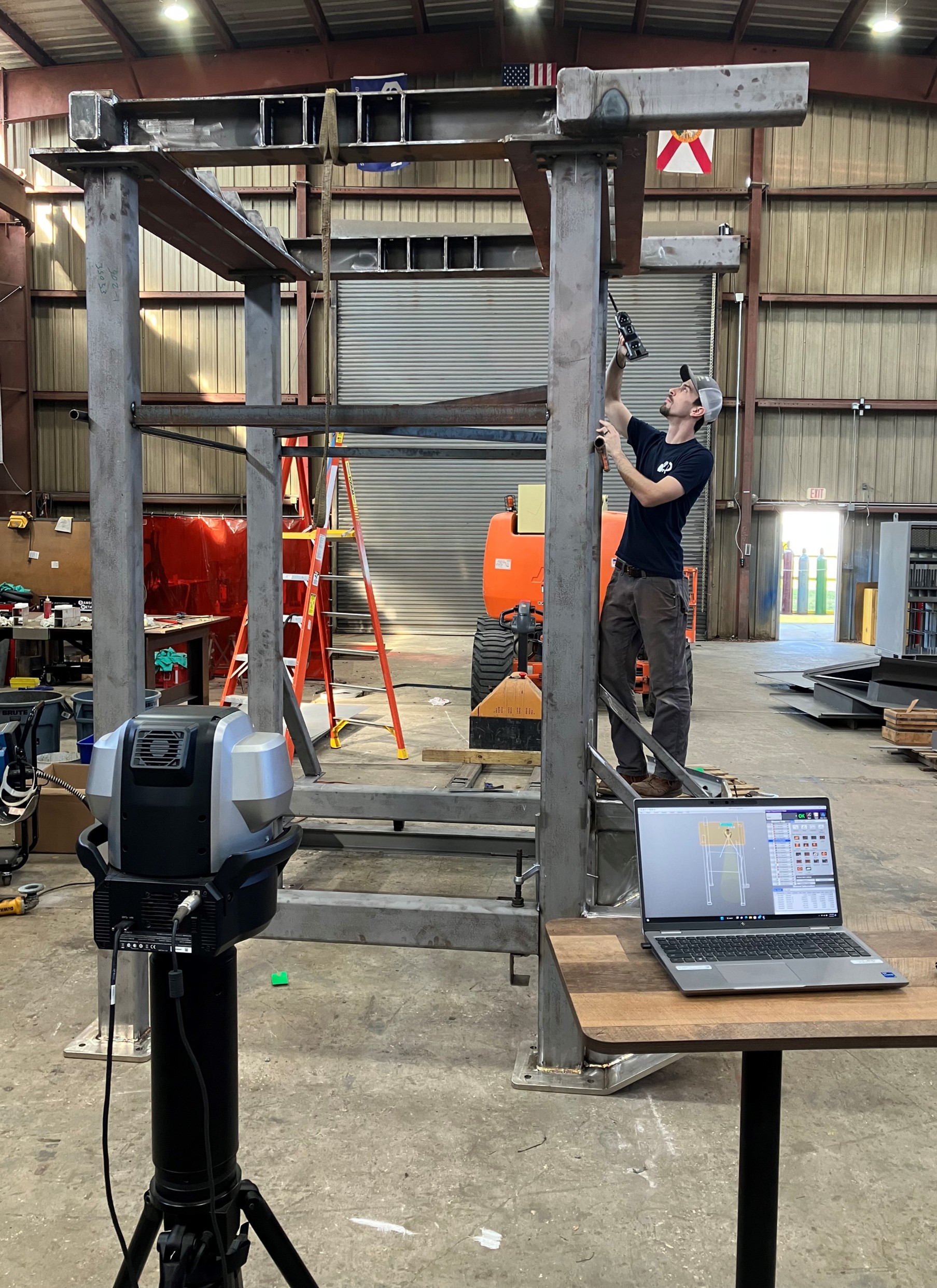

2. Portability for Shop-Floor Efficiency

The portability of the Keyence WM-6225 transforms how we conduct inspections. Lightweight and wireless, it can be deployed directly on our shop floor, inside machine tools, or at client sites, eliminating the need for dedicated measurement rooms. The system’s wireless handheld probe, paired with a triple-camera tracking system, uses near-infrared light to capture precise coordinates, allowing us to measure in dynamic environments. This flexibility supports our comprehensive fabrication services, enabling in-process inspections that minimize production downtime. For instance, we can verify components during assembly, enhancing workflow efficiency in our Lakeland facility.

3. Single-Operator Simplicity

We’ve designed our processes to maximize efficiency, and the Keyence WM-6225’s user-friendly interface makes that possible. With minimal training, a single operator can perform complex 3D and Geometric Dimensioning and Tolerancing (GD&T) measurements using on-screen guidance and a single button press. This simplicity aligns with our commitment to precision and efficiency, as highlighted on www.samsonmetal.com, where we emphasize our advanced CMM inspections as part of our quality management system. The system’s automated data recording and report generation streamline our quality control, allowing us to deliver detailed acceptance data packages for clients, particularly in aerospace.

4. High Precision in Challenging Conditions

The Keyence WM-6225 delivers high-accuracy measurements comparable to stationary CMMs, even in the variable conditions of our shop floor. With temperature compensation and robust camera technology, it ensures repeatable results despite vibrations or thermal fluctuations. We use contact probes for precise dimensional checks and laser-scanning probes for detailed shape analysis, enabling us to verify flatness, parallelism, and complex geometries in components like machined aerospace parts or power generation equipment. This precision is vital for meeting the stringent standards of our nuclear and aerospace clients, backed by our 80 years of management expertise.

5. Unrestricted Access with Wireless Probe

The wireless handheld probe of the Keyence WM-6225 gives our operators unmatched flexibility, allowing measurements in hard-to-reach areas like deep holes, angled surfaces, or internal features of complex assemblies. With a touch-screen interface and the camera’s wide field of view, we can approach parts from multiple angles, making it ideal for components like piping or structural steel. This versatility supports our ability to machine and fabricate materials such as titanium, stainless steel, and plastics, as detailed on our website, ensuring we meet diverse project requirements.

6. Streamlined Quality Control and Reporting

The Keyence WM-6225’s software automates data collection and generates detailed inspection reports, enhancing our quality assurance processes. By comparing measurements to 3D CAD models, we produce color maps that highlight deviations, enabling rapid verification of part accuracy. This capability is critical for our in-house Certified Weld Inspectors and quality team, who ensure every project meets AS9100D standards. The ability to provide comprehensive data packages strengthens traceability and builds client trust, especially for aerospace and power generation applications.

7. Cost and Time Efficiency

The Keyence WM-6225 helps us reduce inspection time and operational costs by enabling mid-process measurements and minimizing setup requirements. Unlike traditional CMMs, which demand part transportation and specialized technicians, our portable system allows inspections on the production line, preventing bottlenecks. With no moving parts and minimal maintenance, it lowers our costs, aligning with our focus on efficiency. For example, we use its rapid measurement capabilities to verify components quickly, avoiding rework and ensuring timely delivery for our clients.

8. Versatility Across Industries

The Keyence WM-6225 supports a wide range of applications, reflecting our expertise in multiple sectors:

- Aerospace: Ensuring precision for structural frames and machined components.

- Entertainment: Verifying amusement ride hardware for safety and performance.

- Power Generation: Inspecting pressure vessels and piping for extreme conditions.

- Marine and Mining: Measuring complex assemblies to meet industry standards.

Its ability to handle materials like aluminum, titanium, and plastics underscores our versatility, as showcased on www.samsonmetal.com.

At Samson Metal, the Keyence WM-6225 Wide Area CMM Camera, a product from Keyence Corporation of America, is a cornerstone of our commitment to delivering precision and quality from our Lakeland, Florida facility. Its expansive measurement range, portability, ease of use, and high accuracy empower us to exceed client expectations in aerospace, entertainment, power generation, and beyond. By integrating this technology into our AS9100D-certified processes, we enhance efficiency, reduce costs, and uphold the highest standards. To explore our fabrication and machining capabilities, including our advanced CMM inspections, visit www.samsonmetal.com.